This is the a retroactive post as I play catchup – I performed a lot of work before setting up this page. I started the suspension with the rear end. There is a definite order of operations:

- Do the suspension before putting the engine in so I am dealing with less weight

- I sourced the axles first

- Start at the rear because it is going to set the initial mounting location of the axle and ride height

The rear suspension is leaf spring from the factory and I retained a leaf spring arrangement. It’s very easy to work with and can handle towing a trailer well too. I initially bought a rear axle from an early 2000’s F250. To the best of my recollection this is a 10.5″ Sterling although my feelings wouldn’t be hurt if it were the 10.25″ variant; no locker (that I know of). A lot of people complain that it’s size at the housing is too big and will drag on rocks but again, I don’t plan on doing serious rock crawling. These things are readily available and affordable, and also come with disc brakes which was a requirement for me because I refuse to work with drum brakes these days. Let’s get into it.

First step was removing the old Dana 44. Unfortunately I don’t have pictures of this but it’s pretty self explanatory. Remove shocks, remove U bolts, drop axles. You can leave it on if you want but I’d rather fight the leaf springs without weight hanging from them. Fight leaf springs? The bushings on them always get corroded onto the hangers. It takes patience, big sledge hammers, crowbars, sometimes heat. This year Jeep had a shackle in the rear and a post on the front.

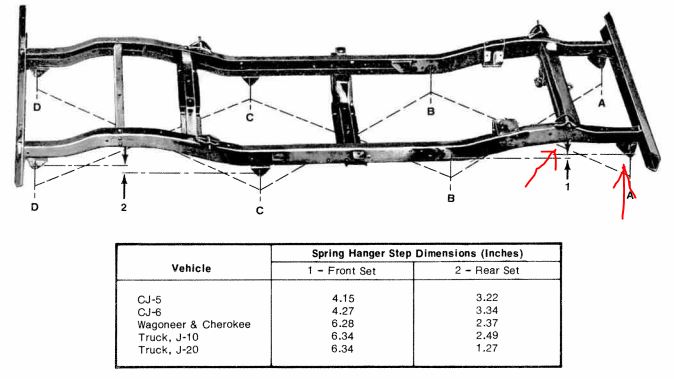

I then sourced replacement F250 hangers. These are easy to find, affordable, and are usually riveted onto Fords but when you replace them you punch out the rivets and replace with bolts which is perfect for what I plan on doing. How do we set the location of the axle? Well, so long as the ride height isn’t outrageous, my only goal is to get the axle centered in the wheel well and across the truck left/right. I don’t know how most people do this, maybe they buy an assortment of leaf springs and find what works, but I had a set that came with the axle. A lot of people like a certain make of GM leaf springs (working from memory) that are long and flexible. I initially looked into that but shied away. They are flexible because they are long, I think 63″. I used websites such as generalspringkc to sort through different options since it easily gives you spring capacity, length, center point. This will dictate suitability for the application. To get the axle centered I need the pin on the leaf spring to be centered in the wheel well. I can then see where the endpoints fall on the frame to determine my mounting locations. I found that with the F250 leaf springs the rear mount landed nicely on the frame (it didn’t extend beyond the frame) and the front mount was going to interfere with the original post. Not great. However, if you look at the F250 mounts, they are built in such a way that I could cradle that post in the center. It is hard to describe so here is a photo:

It required some trimming of the flange around the post but it worked. One important thing to note; the flange is incorporated with a crossmember brace and that brace is held in with rivets, along with the post. I didn’t want to remove it outright because then I’d need to find a clever way to retain the crossmember and at this point in the I didn’t need my frame going floppy by removing the crossmember. I will be circling back to weld in gussets to firmly attach the crossmember to the frame since I hacked the flange a little.

Next I mount the rear bracket. Plenty of space back here. The shackle will go in the rear. I flipped the rear flange so the shackle was on the bottom as compared to the top like on a Ford. This in essence gave me a few inches of lift. The flange is symmetric so if I don’t like it I can flip them over to lower the truck. The rear flange has 6 bolts but because the frame reduces down to 4 inches (?) I could only utilize 4 of them.

Now that we have it mounted we need to address two issues. First, the pedestal on the axle that interfaces with the leaf spring (peg on spring goes into hole in pedestal) is set for the width of a Ford frame. It’s close, about half an inch on either side. However, because I placed my leaf springs wherever I could on the frame, I may have tampered with the pinion angle of the axle. Try to imagine lifting the rear mount very high relative to the front mount, it would crank the pinion down towards the ground and vice versa. I can’t do anything the geometry of the frame, specifically if the rear of the frame is raised relative to the midsection, and by how much.

The leaf spring mounts also push out from the frame ‘by however much’, thus moving the springs outboard by a given amount. Again, it frankly doesn’t matter because it is what it is. The only time it mattered was doing preliminary research to make sure I had enough width on my axle to slide the pedestals out. So to get to the point, we need to remove the pedestals and relocate them. Slide them out to align with the leaf springs, but also rotate the axle to get the pinion angle we need. For reference, we’re talking about this… Looking at the old Dana 44 here because I don’t have pictures of the other.

Here is another photo of them removed.

This process did groove the axle a little so I tried my best to patch it. Warning: grotesque welds. It doesn’t really matter as the tube is 1/4″ wall if I recall correctly.

Since I am going with the F250 springs, I’m going to need to know their spring rate. Annoyingly, no one seems to talk in terms of rate, they usually talk in terms of capacity. Generally speaking these will be far too stiff for this application since an F250 was a heavy duty truck meant for hauling. Ford used all of 2 main leaves with a short helper leaf. Using the website I mentioned above and talking with some folks I decided to remove that helper leaf. We’re going to go with it and if I don’t like it I can buy new ones. I said generally speaking earlier because dependent on the F250, they sometimes came with softer springs (maybe it was just the front springs…) if it came with a gas engine. There may be stock options that are more comfortable so I don’t have to go after market. Since it’s an F250, there’s a ton of these in parts yards and off the shelf. How do I know what capacity I need front and rear? Reference this post: Weight Calculations

Now we are able to line up the axle and mount it up. As it currently sits, its a mock up. I need to get new U bolts and weld on the pedestals once I set the pinion angle. I won’t know the pinion angle until the truck has most of the weight on wheels, along with transfer case installed so I can measure output shaft angle. The F250 axles are wider and push out the wheels. I’m not a fan of wheels sticking out and don’t really want to run flares but we will cross that bridge when we get there. Lastly, the original Dana 44 differential was offset. This axle is centered which will conflict with the fuel tank but lucky for me it’s rusted out and scrap. Of course I don’t have a good photo so I’ll leave with this. I will make a video later summarizing everything in this post and attach.